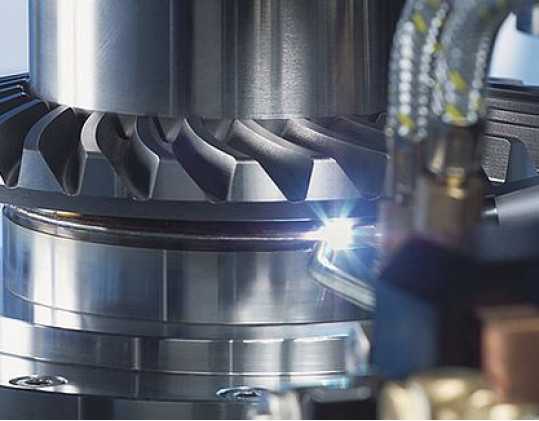

OROTIG is a world leader in the production of solid-state LASER-welding equipment, which emit a pulsed LASER-light. The advantages of this type of welding are best expressed when applied to metals such as gold, silver, platinum, palladium, titanium, stainless–steel alloys, , cobalt-chromium- and nickel-chromium based alloys, cast-iron, and many other pure metals and alloys.

Our range of LASER-welding equipment includes:

|

EVO 100 |

Designed for small businesses, it is not recommended to work with highly reflective metals such as silver and copper. |

|

EVO 125 |

Designed for small businesses, recommended for all metals and alloys. EVO 200 Designed for medium-sized enterprises, recommended for all metals and alloys. |

|

EVO 200 |

Designed for medium-sized enterprises, recommended for all metals and alloys. |

|

MARK-UNO |

Designed for medium-sized enterprises, recommended for all metals and alloys. |

|

R-EVO S |

Designed for medium / large enterprises, recommended for all metals and alloys. The possibility of continuous work 3 shifts per day. |

|

R-EVO PLUS |

Designed for medium / large enterprises, recommended for all metals and alloys. The possibility of continuous work 3 shifts per day. The welding speed is twice as high compared to R-EVO S. |

|

R-EVO 15000 |

Designed for large enterprises, recommended for all metals and alloys. The possibility of continuous work 3 shifts per day. The most powerful machine. It has the highest quality welding. |