- Home

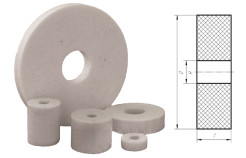

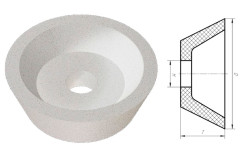

- Ceramic grinding wheels

Ceramic bonded abrasive wheels are designed for machining hard alloys, non-ferrous metals, glass, and steel. The ceramic bond has high refractoriness, water resistance, chemical resistance, well preserves the profile of the working edge of the circle, but is sensitive to impact and bending loads.

14a - Normal electrocorundum. used in the manufacture of abrasive tools for grinding viscous materials with high tensile strength, for abrasive machining with variable loads, as well as for heavy roughing work and for sandblasting.

25a - White electrocorundum. It has high hardness, strength, heat resistance, high brittleness and high cutting ability, it has an insignificant number of impurities and is more uniform in composition. Used for machining hardened hard steels.

64c Silicon carbide green. Due to its high hardness and cutting ability, it is used mainly for the production of abrasive tools and for free grinding. It is necessary for grinding iron, hard alloys, non-ferrous metals, stone, glass